How the spot welding process works

Wiki Article

Spot welding process

How does the contact welding process work? How is it that two parts are connected to each other at just one point, and how can you trust the manufacture of, for example, car bodies if the entire body part is welded in its entirety, but only a few points? Do you know all the answers to these questions? – No? – Then we recommend that you familiarize yourself with the technology of the spot welding process.

How does the contact welding process work? How is it that two parts are connected to each other at just one point, and how can you trust the manufacture of, for example, car bodies if the entire body part is welded in its entirety, but only a few points? Do you know all the answers to these questions? – No? – Then we recommend that you familiarize yourself with the technology of the spot welding process.

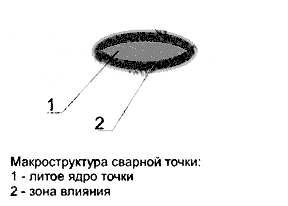

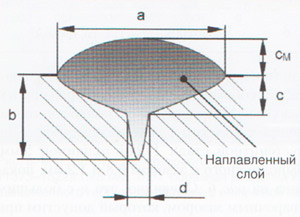

So, together with the inclusion of the welding machine, the current is turned on, which passes in the direction from one electrode to the second electrode, passing through the metal of the parts. Thus, the current heats the metal of the parts precisely at the point where the two electrodes touch. The heating of the surface of the other section of the metal, as is correct, is not too great, because the contact electrode has a low resistance, high electrical conductivity of the metal, and in addition, the electrode can still be intensively cooled by water cooling. Well, when the metal and the electrode collide, heating and melting are created in the welding area, creating a welded spot that has a lenticular shape. As a rule, the diameter of one such spot varies within 4-12 mm.

Also, spot welding is possible without melting the metal and the core of the spot, but due to its manufacturability, such welding is not reliable enough, and is used only in low-tech welding processes (low-carbon steel is usually welded). Welding of metal that has insufficient weldability occurs only when a melt in the core forms a metal spot.

The essence of spot welding does not end only with the creation of points on the metal surface. It also consists in giving the parts a cast design of the welded joint, due to the application of a significant force of sedimentary pressure. In this case, the pressure must be necessary to overcome the rigidity of the product, and if necessary, to make plastic deformation, after which the spot welding is applied, i.e. welded points.

It is also worth noting that with a large thickness of the metal, the load on the electrodes becomes extremely large, so the service life of the electrodes is noticeably reduced. That is why spot welding is mainly used for welding thin sheets of metal, and with increasing thickness, the size of the electrodes (and the welding machine itself) also increases. As a rule, the largest welding thickness remains in the region of 5-6 mm, and in rare exceptions it can reach 12 mm.

If the wrong welding method is selected for the workpieces, the welding machine may simply not have enough pressure and current to weld the two parts, and as a result, a fusion (actually, a point) will not be obtained.

Source: Zvarka.info

Report this wiki page